INSTRUCTIONAL VIDEO

MAX BOND Low Viscosity A/B

Laminate Configuration Flat Panel

Used For Structural Applications

Room Temperature Cured

Hexcel 7781 9 Ounce 8-harness Satin Weave Top And Bottom Plie Plus 15 Layers Core 24-ounce Fiberglass Plain Weave Roving

Laminate Configuration Contoured Speaker Enclosure

MAX CLR-HP A/B Used

For Carbon Fiber Crystal Clear High Performance Single Ply 12-ounce 2×2 Twill Weave Carbon Fiber

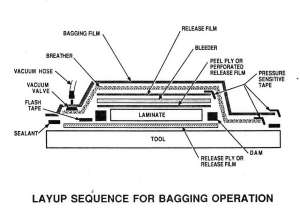

Given enough time and the proper selection of the fabric’s surface treatment (fabric to resin compatibility), a dry fabric will seek a state equilibrium and distribute the applied resin and naturally release air bubbles entrapped within the laminate. It is then very important that the proper viscosity, working time and surface treatment of the fabric must be considered depending on the application of the composite structure. There are also fabricating techniques that can be employed to yield high performance laminates. Depending on the size of the part, processes such as high pressure pressing, vacuum bagging and vacuum assisted resin transfer molding are superior methods over hand dry lay-up. Air voids or porosity within the laminate is typically where failure propagates when load is applied (fracturing, compression failure, tearing, torque, tensile strength, creep).

Vacuum Resin Fusion Process With MAX 1618 A/B