Step Two: Choosing the best epoxy resin system

FRP- FIBER REINFORCED PLASTIC.

The epoxy resin used in fabricating a laminate will dictate how the FRP will perform when load or pressure is implied on the part.

To choose the proper resin system consider the following factors that is crucial to a laminate’s performance.

| Size & Configuration of the Part | Number of plies and contoured, flat or profiled |

| Consolidating Force | Free standing dry or hand lay-up, vacuum bag or platen press curing capabilities: heat cured or room temperature cured |

| Load Parameters | Shearing force, torsional and directional load, beam strength |

| Environmental Exposure | Operating temperature, ambient conditions, humidity, chemical exposure, cyclic force loading |

| Material and Production Cost | Buying in bulk will always provide the best overall costs as well as doing it right the first time. |

These factors will dictate the design and the composition of the part and must be carefully considered during the design and engineering phase of the fabrication.

Our General Epoxy Resin System Selection Formulated for Specific Applications

In most instances our MAX EPOXY SYSTEMS epoxy system can be stored at room temperature and remain liquid for up to six months and longer.

MAX BOND THIXOTROPIC A/B

Marine Grade High Strength Adhesive

MAX BOND THIXOTROPIC 64-OUNCE KIT

MAX BOND LOW VISCOSITY A/B

Marine Grade Structural Epoxy Resin

MAX BOND LOW VISCOSITY MARINE GRADE 1-GALLON KIT

MAX HTE A/B

High Temperature Epoxy Resin System

MAX HTE 80 OUNCE KIT

MAX PCR A/B

Wood Rot Repair & Protective Coating

MAX PCR 1.5 GALLON KIT

MAX GRE A/B

Gasoline Resistant Epoxy Resin

MAX GRE 48 OUNCE KIT

MAX GPE Colored Epoxy Resin

Available in White, Black, Yellow, Red, & Blue

MAX GPE YELLOW A/B 1.5 GALLON KIT · MAX GPE RED A/B 1.5-GALLON KIT

MAX GPE BLUE A/B 1/5-GALLON KIT · MAX GPE WHITE A/B 1.5 GALLON KIT

MAX GPE BLACK A/B 1.5 GALLON KIT

MAX GPE A/B

Clear Low Cost General Purpose Epoxy Resin

Safe To Use on Polystyrene Foam

MAX GPE CLEAR 48 OUNCE KIT · MAX GPE CLEAR 96 OUNCE KIT

MAX GPE CLEAR 1.5 GALLON KIT

MAX CLR Clear Liquid Resin System**

Low Viscosity Version Extended Pot Life and Improved Flexibility

MAX CLR LOW VISCOSITY 24 OUNCE KIT· MAX CLR LOW VISCOSITY 96 OUNCE KIT

MAX CLR LOW VISCOSITY 1.5 GALLON KIT · MAX CLR LOW VISCOSITY 7.5 GALLON KIT

MAX CLR FAST

30% Faster Setting Version

MAX CLR FAST 24 OUNCE KIT· MAX CLR FAST 1.5 GALLON KIT

MAX CLR-HP

High Performance Version With Higher Heat Resistance, Toughness, and Surface Hardness

MAX CLR HP 24 OUNCE KIT· MAX CLR HP 96 OUNCE KIT

MAX CLR HP 1.5 GALLON KIT · MAX CLR HP 7.5 GALLON KIT

MAX CLR TC

Improved Degassing and Surface Quality – For Top Coat Use Only

MAX CLR TC 96 OUNCE KIT

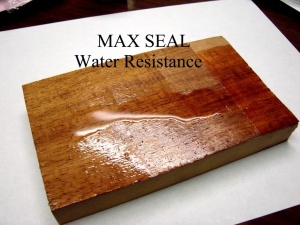

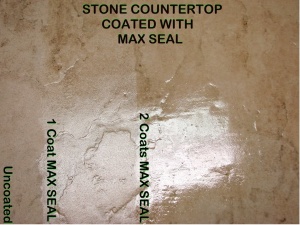

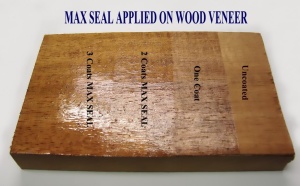

MAX SEAL

NON-YELLOWING ALIPHATIC POLYURETHANE TOP COAT

MAX SEAL 1 QUART

MAX SEAL 1 GALLON

** An ALIPHATIC BASED TOP COAT REQUIRED FOR OUTDOOR AND DIRECT SUNLIGHT APPLICATION

<<<Return to Composite Fabricating Basics Step 1: Fabric Selection

>>>Continue to Composite Fabricating Basics Step 3: Proper Layup Technique